Embarking on a journey through modern industries’ digital and automated landscapes, Siemens Central Processing Units (CPUs) emerge as pivotal components, orchestrating the seamless and efficient operations of various systems. Siemens, synonymous with innovation and quality in industrial automation and control, has developed a diverse array of CPUs, each tailored to meet specific needs and applications across myriad sectors.

Siemens CPUs serve as the nerve center of their automation systems, meticulously managing, controlling, and executing operations, ensuring that processes unfold with precision, reliability, and efficiency. In the vast and complex world of industrial automation and control, these CPUs manage data, execute commands, and control peripherals, and ensure that the entire system communicates cohesively, ensuring optimal performance and reliability.

The importance of Siemens CPUs is underscored by their ubiquity in various industrial applications, from managing intricate manufacturing processes and ensuring safety in critical systems to optimizing data handling and communication in diverse automated environments. Siemens has crafted a variety of CPU types, each with distinct features and capabilities, to cater to the varied demands of different industrial applications.

In this exploration, we will delve into the intricate world of Siemens CPUs, unraveling their types, defining their functionalities, and exploring their applications in real-world scenarios. Whether you are navigating through the complexities of large-scale manufacturing, ensuring safety in critical applications, or managing data in intricate automated systems, Siemens CPUs stand out as reliable, efficient, and innovative solutions, driving forward the capabilities of modern industries.

Table of Contents

Understanding Central Processing Units (CPU)

In the intricate world of computing and automation, the Central Processing Unit (CPU) emerges as the linchpin, seamlessly orchestrating operations, managing data, and ensuring the coherent functionality of systems. Let’s delve into the foundational aspects of CPUs, exploring their definition, basic functionality, and pivotal role in computing and control systems.

Definition and Basic Functionality of CPUs

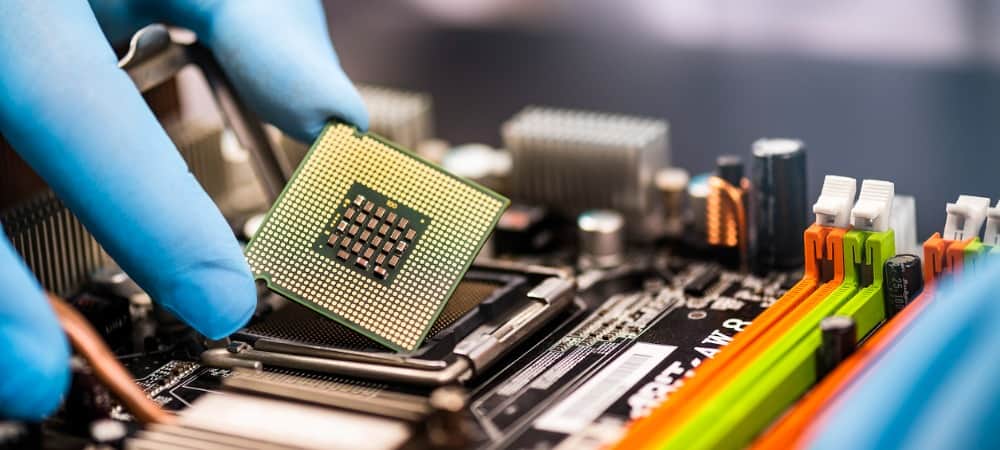

A Central Processing Unit (CPU), often referred to as the brain of a computer or automation system, is a hardware component that executes instructions and manages the operations of a computer by performing basic arithmetic, logic, controlling, and input/output (I/O) operations. It interprets and processes instructions from hardware and software, manages data flow, and coordinates the activities of all the other hardware components in the system.

In essence, the CPU takes input data, processes it according to the instructions provided, and produces output, thereby driving the system’s functionality. It performs this through a cycle of fetching instructions, decoding them, executing them, and then providing the relevant output, ensuring that the system operates efficiently and effectively.

Role and Importance of CPUs in Computing and Control Systems

In computing systems, the CPU plays a crucial role in ensuring that all software applications run smoothly, managing data processes, and facilitating user interactions with the system. It ensures that instructions are executed, operations are manipulated, and data is handled efficiently, providing a smooth and responsive user experience.

In the context of control systems, especially in industrial automation, the CPU takes on an even more pivotal role. It manages data, executes instructions, and ensures that all peripheral devices, such as sensors, actuators, and communication modules, work harmoniously. The CPU processes input data from sensors, executes control algorithms, and sends commands to actuators, ensuring the control system responds accurately and reliably to controlled processes or environment changes.

Siemens CPUs, which we will explore in the forthcoming sections, embody these principles, providing robust, reliable, and efficient solutions in both computing and control systems across various industries. From managing intricate industrial processes ensuring precision and reliability in manufacturing to optimizing data communication in automated systems, Siemens CPUs stand out as quintessential components, driving forward the capabilities and possibilities of modern industrial applications.

Types of Siemens CPUs

Navigating through the extensive portfolio of Siemens CPUs, one encounters diverse options, each meticulously designed to cater to specific applications and scenarios within industrial automation and control. With a keen understanding of the varied demands of modern industries, Siemens has developed different types of CPUs, ensuring that the unique requirements of other applications are met adeptly.

Standard CPUs

Definition and Basic Features: Standard CPUs from Siemens are designed to offer a balanced performance for a wide range of automation applications. They provide adequate processing power, memory, and communication capabilities to handle various tasks in industrial automation, ensuring reliable and efficient operations.

Applications and Use-Cases: Standard CPUs find their utility in a multitude of applications, including manufacturing processes, assembly lines, and other scenarios where reliable control, data processing, and communication are paramount without necessitating specialized functionalities.

Compact CPUs

Definition and Distinguishing Features: Compact CPUs are characterized by their compact design and are typically optimized for applications with premium space. Despite their smaller footprint, they offer robust performance and are equipped with integrated inputs and outputs, providing a compact yet powerful solution for automation tasks.

Where and Why They Are Used: Compact CPUs are often utilized in applications where space constraints are prevalent, such as compact machinery, distributed systems, or scenarios where a lightweight, streamlined control solution is desired without compromising performance.

Failsafe CPUs

Explanation and Key Characteristics: Failsafe CPUs are engineered with a focus on safety and are designed to manage and execute safety-related applications. They are equipped with features that ensure reliable operation even in the event of faults or disruptions, ensuring that safety-critical processes are managed effectively.

Applications in Safety-Critical Scenarios: These CPUs are predominantly used in scenarios where safety is paramount, such as in process industries, automotive manufacturing, or any application where a failure could result in hazardous situations, ensuring that processes are managed safely and reliably.

Technology CPUs

Overview and Defining Features: Technology CPUs are specialized units that handle specific technological functionalities and tasks. They are often equipped with features and capabilities that cater to specialized applications, such as high-speed counting, precise positioning, or advanced motion control.

Use-Cases Involving Technological Functionalities: Technology CPUs find their place in applications that demand specialized technological functionalities, such as precise motion control in CNC machinery, advanced process control in manufacturing, or any scenario where technical technological tasks must be executed reliably and efficiently.

Selecting the Right Siemens CPU: Factors to Consider

Choosing the appropriate Siemens CPU for your automation and control needs is paramount to ensuring optimal application performance, reliability, and efficiency. Various factors must be meticulously considered to select a CPU that aligns with your requirements and scenarios. Let’s explore some pivotal aspects that should guide your selection process:

Memory and Data Handling Needs

Consider your application’s data storage and management needs, ensuring that the chosen CPU provides adequate memory and robust data handling capabilities to manage variables, logs, and operational data effectively.

Safety and Security Considerations

Evaluate your application’s safety and security demands, opting for CPUs that provide the necessary safety features (such as Failsafe CPUs) and ensuring that security features align with your system’s vulnerability and risk assessments.

Scalability and Future-Proofing

Consider your system’s future needs and potential expansions, ensuring that the chosen CPU can accommodate future developments, additional modules, or increased performance demands.

Cost and Budget Considerations

Evaluate the cost-effectiveness of the CPU, ensuring that it provides the necessary features and performance without overshooting your budget and considering the total cost of ownership over the system’s lifecycle.

Conclusion

Navigating back through our exploration of Siemens CPUs, we have traversed through their definitions, functionalities, types, applications, and challenges and peered into the future developments anticipated in their journey. With their robust capabilities, diverse options, and innovative features, Siemens CPUs have proven pivotal in driving industrial automation and control across various domains.