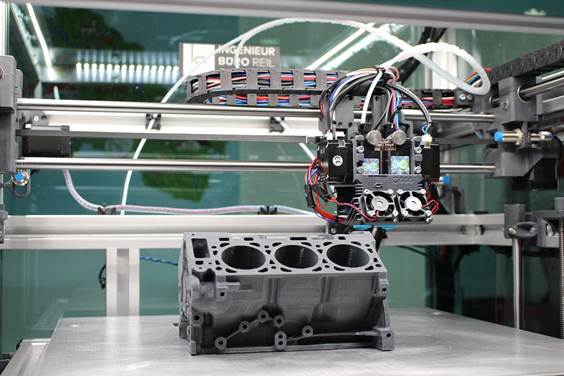

3D printing has been a burning topic in the 21st century. People have been working with 3D printers and have tried to create many objects. Flexible filaments are widely useful material and can be used to create any complex elastic design. Since we are talking about 3D printing, let’s discuss 3D printing with flexible filaments.

If you are new to this you may experience a lot of challenges and it may not be easy. However, printing with flexible filament is easier than it looks. This concept is widely used from TPE to Soft PLA. If we talk about the design these filaments are actually printable rubber and due to this, it allows to create complex elastic designs which may be impossible otherwise. These filaments are available in different varieties. There are different colors, hardness, and chemical make-ups which helps you in applying different properties to your product.

What is Flexible 3D Printing?

Most people would want to know what exactly is Flexible 3D printing. If you have printed with PLA filament you will know that they are hard and brittle. The products which are used to create the models are mostly rubber which can be heated and given the required shape as per the need. This does not work with 3D printers. You will have to combine different materials such as rubber polymers with plastic polymers to create Thermoplastic Elastomer (TPE). Similarly, you can create Thermoplastic Polyurethane (TPU), Polyester Copolyamide Thermoplastic Elastomer (PCTPE), or Soft PLA. These materials are used in many industries to create various items. Most of these items are used in a vehicle. Similarly, if you are printing with resin filaments you can even make eatable products. Rules of 3D printing

There are certain rules which need to be followed when you are using the flexible filament for printing.

- No retraction while printing

The first rule is that there should be no retraction. It is better to turn off the retraction while printing. If you constantly extrude and retract, it can cause issues. The printer will have to refill the hotend with more filament and it can cause errors in the end product.

- Keep the filament dry

It is imperative that you dry the flexible filament every time. It can be done by placing the filament in an oven at 200F for around 6 hours and then switch off the oven and let it cool to room temperature. Most filaments will break if you use them wet. The water drops can also leave voids in the final print which may not look good. If you keep the filament dry it will be good for the end product. The resins are available in many forms hence it can be easily used to create 3D printer objects. A high-quality resin is mostly used for printing with resin filaments. It helps to create a naturally smooth surface.

- Go slow

With certain filaments like PLA or ABS, you can print very fast as they are hard material and easy to move on the product. This is not true for flexible printing. If you slow down the whole process the chances of error are less. You can start 30 mm/s as the maximum speed when you are starting. In case of certain printers you may have to go faster or slower but the 30mm/s is the best fit.

There are certain myths when it comes to using flexible filaments for printing. Many believe that you cannot use this for Bowden style printer and it will not even print well. With the recent advances, the biggest improvement is constraining the filament path. This will make sure that the filament does not come out of the bind and stays in place.

The First Layer

It is always important to get the first layer right in any printing. To achieve that you need to make sure that the print surface is in level. Also, the extruder needs to be at correct height from the bed and the nozzle is at the right distance from the bed. Last but not the least, the base should be of good material and should adhere to the flexible filament. Make sure that the temperature is also correct and too high and too low temperature will be bad for the end product.

Conclusion

With the ever-growing interest in 3D printing and inventions of new ways to create a model has made this a very important work. Soon it would change the way we create and handle object and even food items.